Tongda Tdl

Basic Info.

| Model NO. | TDL-GI |

| After-sales Service | 1year |

| Temperature Difference | About 1 Centigrade |

| Surface Temp | 260 Centigrade |

| Heating Method | Hot Oil Circulation |

| Structure Style | 2/3 Roll |

| Working Width | 1800mm-3500mm |

| Mechanical Speed | 4000mm/Min |

| Working Pressure | 100kg/Cm |

| Transport Package | Nude Packing or as Per Customer′s Requirement |

| Specification | 35000*20000*4000mm(L*W*H) |

| Trademark | TONGDA |

| Origin | China |

| HS Code | 8449009000 |

| Production Capacity | 10sets/Month |

Product Description

TONGDA TDL-GI Glue Free Wadding Production Line Wool Felt Non-woven Fabric Production Machine Line

Textile Nonwoven Wadding Production Line Non Woven MachineTONGDA Non woven Fabric Manufacture Machine Production Line can manufacture different various fashionable patterns types. Thermal Bonded Wadding Non woven Fabric/Geotextile Non woven Fabric/Car Interior Automotive Fabric/Water Proof Material /Glue Free Wadding Line /Filter Felt /Wool Felt Non woven Fabric/ Synthetic Leather Non woven Fabric. These machine is produced by years of research and experiment of all our technical staff. High-performance, and simple operation, strong characteristics of a new type. Apparel trade, industry, interior decoration, etc. in the sewing industry, user love to use these new type of machine. Function and characteristics ♥ The machine is used to process the web to obtain the required hard and thick thermal-bonding wadding.♥The low melt fiber will combine other fibers together through hot air penetration and cooling system for reinforcement.♥To make thermal bonding wadding for garment, mattress, chemical bond wadding, 3M-Thinsulatewaddings for lining, quilts, home textiles, and so on.Structure

♥ Single pass double-belt structure♥ Top and button belts hold the fiber batt on oven entry to allow it to be heated whist forming its structure.♥ The gap between the belts may be adjusted within the range of 50~250mm♥ The belts are of manganese base material coated with TEFLON♥ Unique special air duct design allows hot air to penetrate from either up or down

Main specifications of this nonwoven machine

| Fiber type | natural fiber or synthetic fiber etc. |

| Working width | ≤9000mm |

| Capacity | 300kg/day-5ton/day |

| Product weight | 100~9000gram/m2 |

| Product thickness | 3~200mm |

| Installed Power | 7-11kw |

| Output Width | 2500-10000mm |

| Lapping Speed | 35m/min |

| Needle Stroke | 25-50mm |

| Needle density | 4000-8000n/m |

| Needle frequency | 800-1200r/min |

| Needle type | single board/double board, up/down stroke |

| Working pressure | 100kg/cm |

| Mechanical speed | 4000mm/min |

| Surface temp. | 260 Centigrade |

| Structure style | 2/3 roll |

| Heating method | hot oil circulation |

| Surface temp | ≤220°C |

| Heating method | hot oil circulation, electricity heating, direct burning |

| Oven working wifth | 4.8m-9.0m |

| Fiber type | natural fiber or synthetic fiber etc. |

| Working width | ≤9000mm |

| Capacity | 300kg/day-5ton/day |

| Product weight | 100~9000gram/m2 |

| Product thickness | 3~200mm |

| Installed Power | 7-11kw |

| Output Width | 2500-10000mm |

| Lapping Speed | 35m/min |

| Needle Stroke | 25-50mm |

| Needle density | 4000-8000n/m |

| Needle frequency | 800-1200r/min |

| Needle type | single board/double board, up/down stroke |

| Working pressure | 100kg/cm |

| Mechanical speed | 4000mm/min |

| Surface temp. | 260 Centigrade |

| Structure style | 2/3 roll |

| Heating method | hot oil circulation |

| Surface temp | ≤220°C |

| Heating method | hot oil circulation, electricity heating, direct burning |

| Oven working wifth | 4.8m-9.0m |

Main specifications of this nonwoven machine

| Fiber type | natural fiber or synthetic fiber etc. |

| Working width | ≤9000mm |

| Product weight | 100~9000gram/m2 |

| Product thickness | 3~200mm |

| Surface temp | ≤220°C |

| Heating method | hot oil circulation, electricity heating, direct burning |

| Oven working wifth | 4.8m-9.0m |

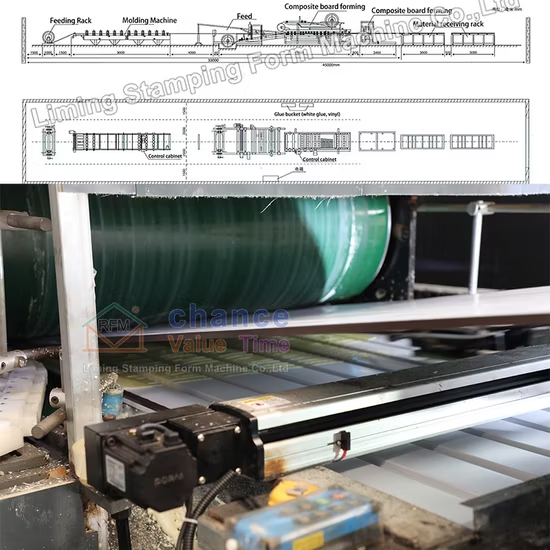

Picture of heating oven/nonwoven machines

The Glue Free Wadding Line/Wool Felt Non-woven Fabric Production Machine Line uses low-melt or bi-component fiber mixed with normal fiber in properties to create stiff waddings, or such as foam replacements for cushion, mattresses, acoustic and insulation felt, etc. It also able to make soft wadding for interlinings such as home textiles, garments, furniture, toys etc.The material after forming into a batt is passed through a oven with stainless steel or belt dependent on the products. Where fitted the top belt is a moveable compression belt. However, for soft waddings, e.g. lofty material below 1500 gram per square meter, it is normal to use belts in the oven. Production lines can make all kinds of needle punching geotextile or other needle punching products. The line can have additions such as batt and 1 or felt drafters. Needle looms of different needle types and 1 or densities can be used depend on end use of product.

FAQ:(1) Q: How's the after-sale service? A: We offer engineers available to service overseas under merchandiser's supervision and translation.(2) Q: Are you available for on-the-spot invitation? A: We do welcome our new and old friends come here to have a visitation. Besides, we would send you our exposition and relative information to promote a face-to-face meeting if you'd like to.(3) Q: Is the price offered changeable? A: We offer reasonable price for every client, and the price is changeable according to purchasing amount.(4) Q: How about the quality? A: The main subassembly and raw materials are all supplied by large companies. Key parts are research and developed by our own staff. Professional assembly line work and strict quality test system can ensure your high quality requirement.(5) Q: Are you a manufacturer or Trade Company?

A: We are a professional manufacturer holding our own International Trade Department, for that we can better understand customer's needs and offer a reasonable price.Why Choose Our Company?

A: History: TONGDA Textile Machinery Group was establish in 1952. Now have more than 65 years old history.B: Main Products: TONGDA Group specializes in design, manufacturing, and marketing of a wide range of Textile machinery, it has seven branch companies, mainly produces ring spinning frame, roving frame, weaving machine (water Jet loom/Air jet loom/rapier Loom), warping machine, quilting machine and nonwoven machine.C: We provide design for complete line of spinning mill for cotton yarn, polyester yarn, wool yarn, flax/linen yarn, machines including blow room, carding machine, draw frame, roving frame, ring frame, winding machine, open end spinning machine and the air conditioning system and waste collection system for spinning mill.We also provide workshop layout design and trench design, and air pipe layout design. D: Product /Quality Guarantee: 1 year warranty for the International standard.E: After Sale Service: We are work online 24 hours. If you have any questions about our machine you can contact us.F: One-stop Service:We have R&D department including more than 100 engineers which are improving and enlarging our supply range.Export Memorabilia:TONGDA 1988: TONGDA's 500 sets ring spinning machines was exported to Bangladesh.TONGDA 1993: TONGDA's 385 sets spinning machines was exported to Pakistan.TONGDA 1995: TONGDA's 229 sets spinning machines was exported to Bangladesh.TONGDA 2002: Delivery 300 sets spinning machines to India.TONGDA 2009: TONGDA's 100 sets water jet loom and air jet loom was exported to India.TONGDA 2010: TONGDA once again exported 300 sets water jet loom and air jet loom to India.TONGDA 2011: TONGDA exported needle punching nonwoven machine production line to south America and exported more than 500 sets water jet loom, air jet loom, rapier loom to overseas.TONGDA 2012: TONGDA exported 200 sets spinning machine and 100 sets rapier loom to Tajikistan and once again exported 200 sets ring spinning machines to India.TONGDA 2013: TONGDA exported 500 sets weaving machines to overseas and 50 sets nonwoven machines, 680 sets spinning machines to overseas including South Asia and Africa.TONGDA 2015: TONGDA sold more than 1000 sets weaving machines, 100 sets nonwoven machines and 700 sets spinning machines to overseas including Europe, South America, and South-East Asia.Certification:TONGDA is an ISO9001, ISO14001, and ISO13485 company. The products are designed to meet the technical standards of 3C and CE. All the products are certified by the Industry Administration Authority. TONGDA will continue to strive to be a stronger leader in the global market of Cotton machinery and Spinning machinery.Exhibition:Welcome to inquiry: