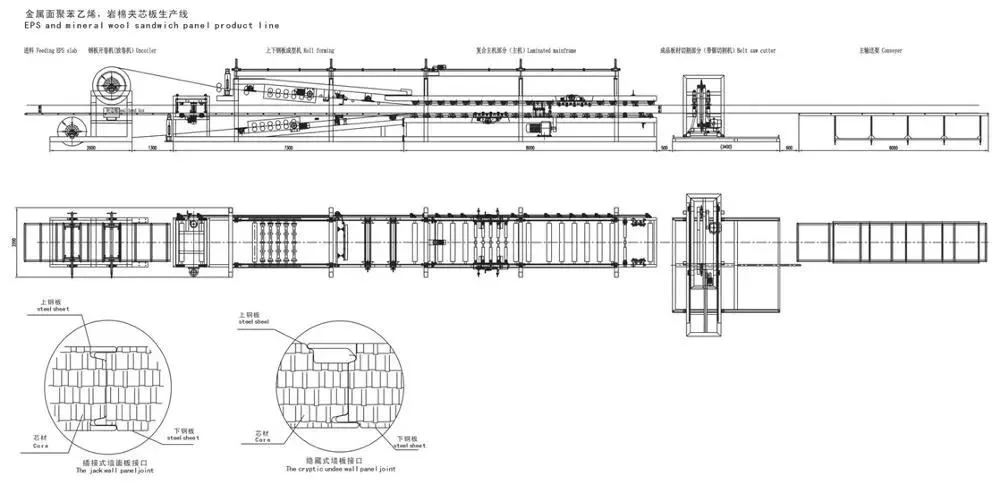

EPS Rock Wool Sandwich Panel Machine Production Line

Basic Info.

| Model NO. | EPS Rock Wool Sandwich Panel Machine |

| Quality | High Guarantee |

| Material of Rollers | Gcr15 with Heat Treament, Polishing |

| Speed | 15-20m/Min |

| Voltage | 380V or as Customer′s Request |

| CZ Interchange | by PLC |

| Cutting Type | Hydraulic Cutting |

| Material Thickness | 0.3-0.8mm |

| Control System | PLC |

| Color | Blue or as Customer′s Request |

| Material of Shafts | 45# Steel |

| Machine Frame | 450 H Steel |

| Drive Mode | Hydraulic Motor or Servo Motor Drive |

| Transport Package | Nude, with Waterproof Cloth and Stow-Wood. Importe |

| Specification | 50000mm*6000mm*1950mm |

| Trademark | HN |

| Origin | China |

| HS Code | 84552210 |

| Production Capacity | 10sets/Month |

Product Description

Product DescriptionEPS Rock Wool Sandwich Panel Machine Production Line

Sandwich panel is a new multi-function construction material for construction and decoration with the advantage of insulation, fire proof and decoration. It is mainly used for public construction, like industrial workshop, supermarket, bulk warehouse, large span roof, and prefabricated house, different kinds of cold storage, air condition room, decontamination chamber, and communication base station.etc. Sandwich panel has been an ideal new construction material with the advantage of high intensity, beauty, easy to construct in a short time.

- Roof panel forming machine adopt the gear reducer to transmit, motor power is 5.5KW, and processing speed is 5.5m/min. The processing speed can be adjustable by step less speed frequency conversion.

- Assemble machine adopt the gear reducer to transmit, motor power is 3KW, and processing speed is 6m/min. The processing speed can be adjustable by step less speed frequency conversion

- Normally processing EPS sandwich panel, the speed is 2.5-6m/min, rock wool, glass wool sandwich panel processing speed will be lower than 1.5-3m/min.

- The whole line speed was controlled by the motor synchronous controller, with step less speed and digital display.

| Name | Eps cement sandwich panel production line |

| feeding width of plate | 1000mm |

| Core thickness | 50-250cm |

| Core material | foam, rockwool |

| Material thickness | 0.3-0.7mm |

| Total power | 32kw |

| Forming speed | 0-4m/min |

| Control system | PLC (Delta )control system full automatic control |

| Material of sandwich production machine | square tube:80*160*9mm |

Woring flow of EPS Rock Wool Sandwich Panel Machine Production Line

Cangzhou Hener Machinery is a professional integrating R & D, production, sales, export and service. We have professional foreign trade sales team, operation team, R & D team and after-sales team. Our R & D cycle for new products is at least 20 days. The working experience of our sales team is 5-6 years. The R & D personnel are all undergraduates. The average equipment maintenance experience of after-sales engineer is 10 years. In order to supply the satisfactory products and services, we have built a modern quality management system which is in strict accordance with international standards.

After Sales Service

1.we can provide all kind of roll forming equipment which can be used to forming all kinds of shape as you required. The company can make non-standard products for client's requirement.

2.About after-sales service. We provide online training for life, you can also come to our company to learn, there will be professional staff to teach, you can also send technicians to your country to repair the machine. The buyer shall bear all costs.

3.The warranty period is 24 months. We will provide you with lifetime technical support. The machine can be repaired free of charge for the first year after purchase, including replacement of main components.

FAQ1. Does your company can customized my needed profile?Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profiledrawingand we can give you our professional machine design solution.2. If i don't have profile drawing, but i want to buy one machine, can you help me?Yes sir/ Madam. If you don't have profile drawings, the solutions have:2.1 : Provide me with your profiles' pictures ;2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you relatedprofile drawings.2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.3. What your company advantages? Our advantages have :3.1: We have completed production system. And more than 20 sets of CNC machines which can support lots of machineorders' making and guarantee the delivery.3.2 : Our sellers abundant experience can guarantee you will have apleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details aboutthe machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy themost suitable machine for you.3.3 : We are a golden integrity roll forming machine company. About the after-sale services, no worries, we will responsible for you.4. Will i receive a good machine ? Same with my wanted ?Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.5. What is the machine minimum quantity?One machine is okay.6. What is your payment terms?6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.6.2 : We accept 100% L/C at sight6.3: We accept Western Union payments.6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.