Double Cylinder Double Doffer Carding Machine of Nonwoven Wadding Thermal Bonding Production Line/Textile Machine

Basic Info.

| Customized | Customized |

| Condition | New |

| Width | 1550mm-3200mm |

| Place of Origin | Shandong, China |

| Power | 54.4kw (1550-2000mm) 61.9kw (2300-2500mm) 88kw ( |

| Weight | Depend on The Width |

| Capacity | <1000kg/H (6D Fiber) |

| Mesh Output Speed | 20 -55m/Min |

| Transport Package | Standard Package |

| Trademark | halcyontex |

| Origin | China |

| HS Code | 84490090 |

| Production Capacity | 20sets/Month |

Product Description

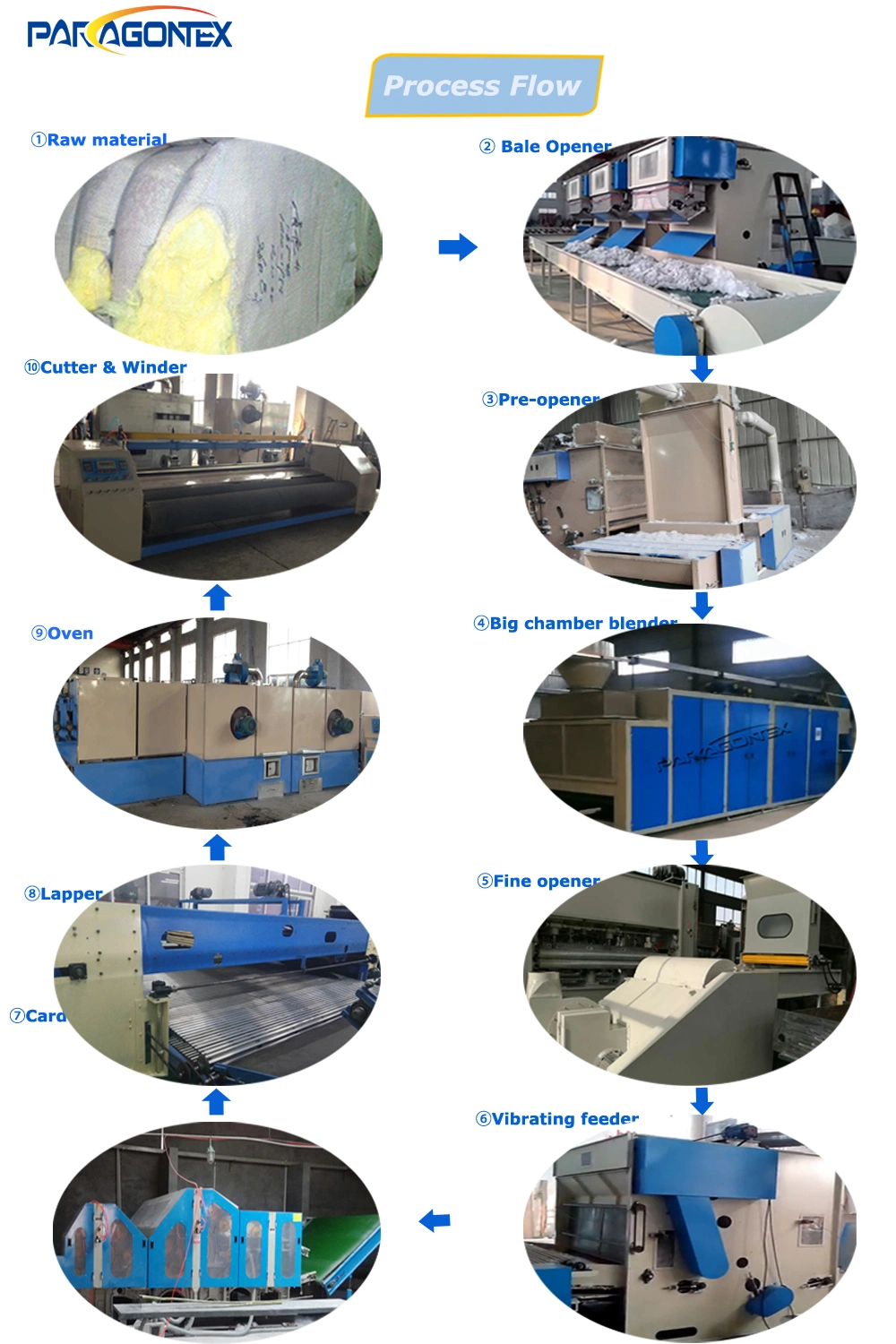

carding machineThis machine is used for fully carding the fiber layer to fiber webs for the next procedure.

The machine with single cylinder high-speed coming and double-doffer output is suitable for carding 1.5D-20DX38-65mm artificial fiber. The cotton feeding roller is controlled by frequency conversion and the machine is equipped with anti-metal protection device

Specifications:

Width: 1550mm, 1850mm, 2000mm, 2300mm, 2500mmMesh output speed: 20 - 55m/min

1.The card is of modular design allowing for ease of transport and installation.

2.It is mounted normally on an 800mm width platform with CE/UL approved walkways allowing for ease of observation and access as required in a safe manner.

3.There is a metal detect system fitted whereby the feed rollers are designed to detect metal and will automatically go into reverse for several seconds to reverse any metal away from the card licker-in. 4.Main cylinder equipped with emergency brake system.

All card main cylinders and main rollers are manufactured in a controlled manner in house and are all dynamically balanced prior to installation.

5.All drives are variable speed and synchronized to allow for full automatic control of machines prior to and after the carding system.

Total sealing of all rollers prevents fiber causing issues with bearing wrap ups.

6.All covers are laser cut to give perfect fit and all of them are raised/ lowered by means of air soring and electrical pusher.

7.Electronic locking and safety protection of the whole machine is standard and complies with UL/CE requirements.

We are professional nonwoven machine many years, in order that we can supply the exact price and corresponding technical data, please kindly confirm your details requirement as follows:1. What's the final products?2. What's the width of the products?3. What's the Gsm( grams per square meter )and thickness of products?4. What's the material you used? And what's the specification of the raw material?5. What's the capacity you need?6. Do you have any pics or samples of our final products?

1.Warranty The warranty period shall be valid for 12 months after completion of the commissioning. During the warranty period, if any defect and fault is discovered, XinLihua grants a prompt action to solve the problem.2.Installation & maintenanceParagon will send one or two engineers to the Buyer's factory to help the Buyer for the installation and commissioning of the production line at the request of the Buyer. The Buyer should provide the allowance , round-trip air tickets, accommodation, workers and translator. The installation and commissioning will take around 15 days to one month according to different production lines.