Jwf1217 Carding Machine of New Model Intelligent and High Production for Sliver Making

JWF1217 Carding Machine of New ModelIntelligent and High Production for Sliver Making 24h Online Customer Service Produc;

Basic Info.

| Model NO. | JWF1217 |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| After-sales Service | Online Support |

| Transport Package | Wooden Cases |

| Specification | L*W*H: 5800*2600*3645mm; 8000KG |

| Trademark | JINGWEI BRAND |

| Origin | Qingdao, China |

| HS Code | 84490090 |

| Production Capacity | 2100 Sets/Year |

Product Description

JWF1217 Carding Machine of New ModelIntelligent and High Production for Sliver Making24h Online Customer ServiceProduct DescriptionJWF1217Carding machine overturned the process structure form for traditional carding machine, bold innovation, using of new materials, new technology. Major adjustments are made in the aspects of layer feeding, core carding area, frame structure, machine gauge adjustment form, web output, and the pursuit of high yield, high quality and intelligent improvement, which can meet the spinning needs of different customers.

Standard Configuration

JWF1217 Carding Mahcine + FT211 Coiler + JWF1177B Chute Feeder(Four-sided exhaust structure) + FT031B auto leveller

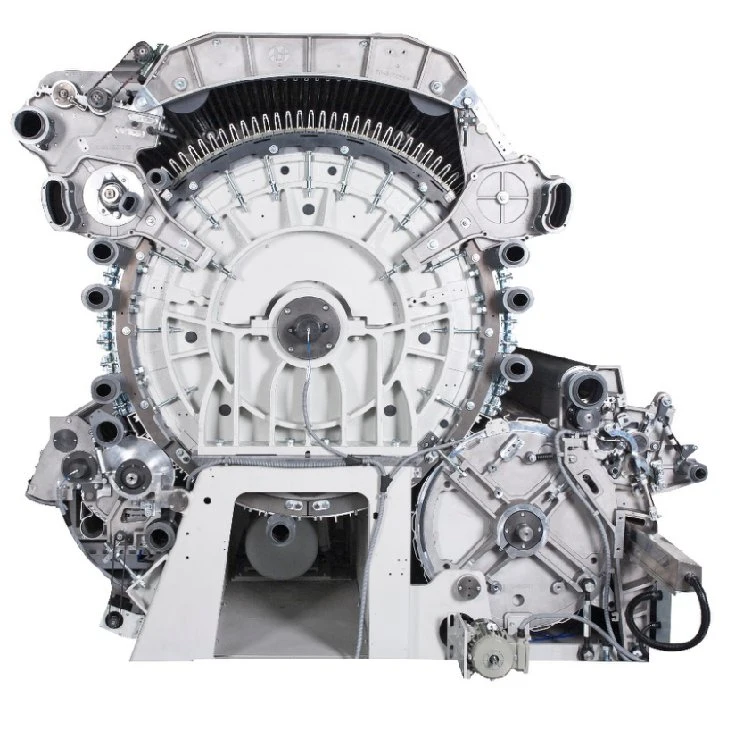

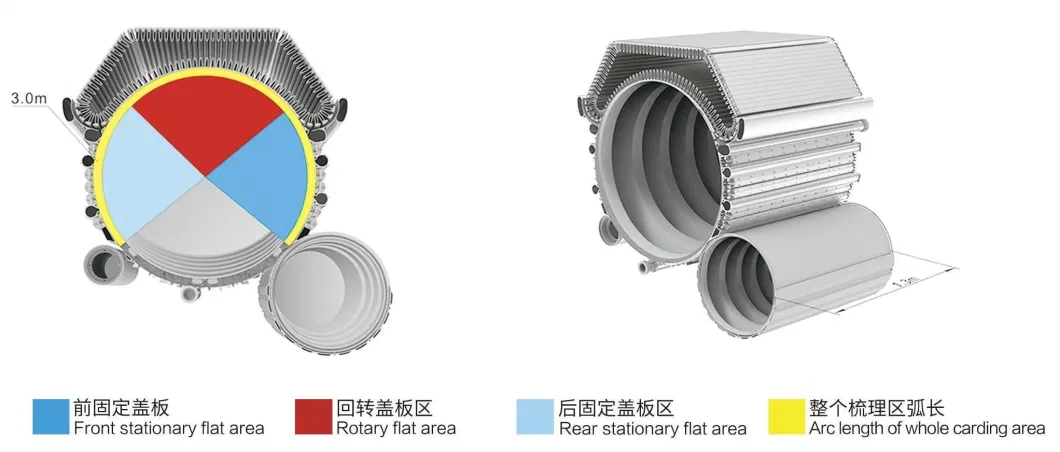

The carding arc length reaches 3 m, the working width is 1.3 m, and the carding area is 3.9 square meters, realizing the reasonable distribution of the front fixed flat area, the rotary flat area and the back fixed flat area, The carding ability is significantly enhanced, which ensures the excellent sliver quality and has the higher productivity.

The number of working rotary flat is the key of the sliver quality.Therefore JWF1217 increased its working rotary flat number to 38 pcs, which improve the effective carding area and carding ability. The rotary flats adopt 9-point gauge setting to ensure the accuracy and stability of the gauge then achieve better effect.Bigger-Diameter Feeding Structure, Which Enhances the Fiber Holding and Improves the Feeding Efficiency.

The bigger-diameter feeding roller is adopted to strengthen the holding of fibers, to improve the opening, feeding and carding efficiency in the licker-in area.Multi-Indepedent Transmission

Cylinder, licker-in, rotary flat, brush roller are all driven by independent inverter motor for more conveient technology adjustment. Feeding roller, big calender, doffer and three rollers adopt independent servo drive, more precise control, suitable for high speed and high capacity demand.Intelligent Improvement

Adopting a new nodel of human-machine interface, achieves functions such as process classification, permission unlocking, convenient operation, etc, effectively showing the operating status. Intelligent protection functions such as cylinder wire touching protection, temperature monitoring in carding area, and metal detection to improve the safety performance of the carding machine in all aspects. Optional flat gauge on-line detection, nep on-line detection, noil on-line detection, etc. can monitor the gauge,quality index and noil situation in real time during the operation of the equipment, to ensure long-term reliability and stability of sliver quality.

| MAIN SPECIFICATION | |

| Type | JWF1217 |

| Max. output (kg/h) | 200 |

| Max. sliver delivery speed (meter/min) | 400 |

| Sliver count(g/m) | 3.5~10 |

| Feed weight(g/m) | 400~1300 |

| Working width(mm) | 1280 |

| Total draft folds | 40~370 |

| Licker-in working dia.(mm) | φ250 |

| Licker-in working speed(rpm) | 700~1200 |

| Doffer working dia.(mm) | φ706 |

| Doffer working speed(rpm) | 3~120 |

| Cylinder working dia.(mm) | φ1288 |

| Cylinder working speed(rpm) | 330~550 |

| Pieces of rotary flat(working/total) | 38/108 |

| Flat working speed (mm/min) | 70~400 |

| Attached Front stationary flats | Licker-in carding: 2(Pieces) Front stationary flats: 10(Pieces) Back stationary flats: 10(Pieces) |

| Web cleaner | Front 3,Back 3 (Cotton) Front 2, Back 2 (Chemical fiber) |

| Continuous air suction volume(m³/h) | 4500 |

| Statistic pressure at exit(Pa) | -800 |

Compressed air pressure (MPa) | 0.6-0.8 |

Compressed air consumption(m³/h) | 0.5 |

Total power installation(kW) | 15.74 |

Safety cover type | Totally enclosed |

Overall dimension(LxWxH)(mm) | 5800*2600*3645 (mm) |

Machine net weight(kg) | (about) 8000 |

Matched chute model | JWF1177B |

Matched coiler model | FT211 |

You may also like

Send inquiry

Send now